Whites Equipment

WER equipment has been drilling horizontal wells at all depths within the Utica, Marcellus and surrounding northeastern formations for 7 consecutive years. This includes over 825 wells in production that were drilled using WER backyard equipment as of JAN 2015. During this successful tenure our field technicians and engineers have experienced all types of hazards under all seasons and climates. This experience has allowed our engineers to refine equipment durability, efficiency and most importantly SAFETY.

Vented Air Bust

The patent pending Vented Air Buster is the most technologically advanced air/gas drilling separator within the industry today.

Vented Air Bust

The patent pending Vented Air Buster is the most technologically advanced air/gas drilling separator within the industry today.

Overview

Performance & Safety features that separate the VAB from competitors:

- 100% Fluid Seal – The only Drilling Separator with a 100% fluid barrier that seals off air/gases preventing any potential hazardous gases from hovering above the solids- control pits.

- 12” High-Volume Plumbing – The only Drilling Separator engineered with 12” high volume inlet & discharge outlet, largest available on the market. Minimized downtime, increased speed and reduced frequency of pack-offs.

- De-Foaming Efficiency – Built-in de-foaming system assists operator with a controlled injection rate and minimal waste. Foam is most concentrated inside the VAB and accuracy of treatment reduces expensive chemical costs on every well.

- Cuttings Filtrate Discharged by H2O Jets & Gravity – The only Drilling Separator utilizing internal water jets that initialize the stages of solids filtration. As cuttings circulate within the VAB they are separated and the filtrate particles fall to the bottom for discharge.

- Quality Built – 100% USA built with USA made heavy-duty carbon steel. Stringent weld inspections, 4-phase quality control inspection, hydro-tested, and fabricated to meet or exceed AWS, ANSI and ASME code standards.

- SAFETY – 7 Years of closed-loop experience has allowed our engineers to hone equipment SAFETY and durability. Not only is the VAB equipped with over-pressure pop-off valve, it is also equipped with an advanced customizable alarm.

Safety & Performance Alarm Detail

- Weight - Alerts operator if VAB is above or below specific weight parameters established by drilling consultant.

- H2O Flow - Alerts operator if H2O flow volume is above or below the performance parameters established by drilling consultant.

- No H2O - Warns location to stop operations and inspect water source.

- Back-Up - In the event of power failure, the VAB is equipped with a reliable mechanical version of each alarm above. This is an extra safety precaution in the event of extreme conditions or outside variables.

Mud Gas Separator

Dual 10" Line Inlets with Telescoping base for any logistical variable or height requirement.

Mud Gas Separator

Overview

- Dual 10” Line Inlets

- 1200 GPM Drilling Fluid Flow Rate

- 2,200 CFM Gas Discharge Flow Rate

- Efficient Cleanup Access

- Telescoping base for any logistical variable or height requirement

Catch Tank

Largest secondary catch tank in the industry, safe inspection / testing access for hazardous gasses.

Residual Liquids Catch Tank

Largest secondary catch tank in the industry, safe inspection / testing access for hazardous gasses.

Overview

- Large 40 Barrel Capacity – Largest secondary catch tank in the industry, safe inspection / testing access for hazardous gasses.

- 12” High-Volume Plumbing – Only tank with 12” inlet and outlet, increased flow improves efficiency and SAFETY.

- Designed for NO SECONDARY CONTAINMENT – Limit spill exposures to the primary containment area and cut costs building secondary containments on every pad.

- Automatic Discharge Pump – Low maintenance; place it in the most logistical location and essentially no further maintenance required.

- SAFETY – Equipped with over-pressure pop-off valve, advanced alarm system.

- User Friendly Operation – Simplistic operational controls & safety alerts reduce exposure to human error.

Flare Stack

High volume, High performance. Only flare with a 12” Inlet.

Flare Stack

Overview

- 12” High-Volume Plumbing – High volume, High performance. Only flare with a 12” Inlet.

- Simplistic User Controls – Quickly purge backyard system with powerful venturi spool. Quickly switch from air to fluid drilling with the flip of the control switch. Simple step-by-step instructions for all user experience levels.

- Safety – Equipped with powerful 12” venturi spool that removes gases from entire backyard system on demand. Avoid uncertainty & minimize human error.

- Logistics – Configures to any logistical layout on location. Packs away for efficient trucking at rig move. Securely rack 12” Vent Line and fittings for faster rig-up, rig moves and rig-down.

- Most Powerful Ignitor System – Aggressively tested, burns under virtually any weather condition. Field tested capability to ignite fully submerged under water.

Drive Overs

12' Drive Overs, Dual Core Technology, double sized core provides highest flow volumes.

Residual Liquids Catch Tank

Overview

- Dual-Core Technology – Double sized core provides highest flow volumes.

- Engineered Strong – Higher flow, clog resistant without losing strength.

- Logistics – Hammer unions for two independent 4” line crossings.

- Low Profile – Wide dual core frame provides minimal incline and quick site mobility for vehicles & service equipment.

Halfrounds

250 bbl. Steel Halfrounds, 1/2'' USA Made Carbon Steel, Avoids risk of punctures or leaks.

Halfrounds

High volume, High performance. Only flare with a 12” Inlet.

Overview

- 1⁄2” USA Made Carbon Steel – Avoids risk of punctures or leaks.

- Baffled Filtration Design* – Filtration perforations designed for the VAB. Increased solids processing speed, reduced centrifuge wear, reduced disposal costs up to 50%.

- Centrifuge Efficiency* – Increased speed, cleaner H2O, reduced haul-off and disposal costs on every well.

- 40’ Halfrounds – Standard or VAB Filtration Baffle models available.

- 20’ Halfrounds – for tight locations or specific solids control demands.

* Baffled filtration pits only available for the VAB H2O system.

* Centrifuge efficiency gains logged while operating the VAB H2O system.

Air operated drilling separators do not benefit using equal resources.

Centrifuge

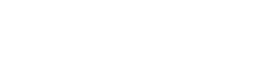

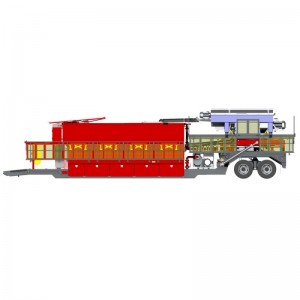

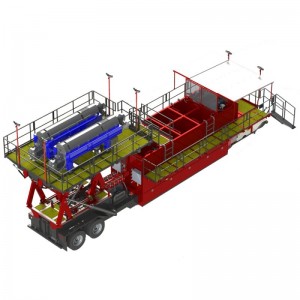

Our patented solids control unit allows you to seamlessly swap from one drilling fluid operation to the next.

Residual Liquids Catch Tank

Largest secondary catch tank in the industry, safe inspection / testing access for hazardous gasses.

Overview

The White’s Equipment Rental patented solids control unit is known for its flexibility to seamlessly swap from one drilling fluid operation to the next. Swapping from the dewatering process to the processing of oil based mud is as simple as opening and closing a few valves. Aside from a generator, this solids control unit is self-contained. The design of the system and the ease of rig ups/downs, allows for the equipment to stay behind on locations during rig moves and process all dirty water. The knowledge and experience of our solids control techs, paired with the efficiency of our centrifuge’s hydraulic handling capabilities allows us to effectively clean all produced water from the well bore.

About the Equipment

- Cuttings Trough

- Service Technicians

WER Unit

- Patented Fluids Management Process

- 2 - 22 bbl Polymer Injection Tanks

- 221 bbl Flocculation Tank

- 25hp 4" Mud Gun Pump

- Hydraulic Dual Centrifuge Platform

WER Centrifuge/ Alpha Laval VFD Lynks 40:

- Fluid Capacity - 440 gpm

- Solids Rate Removal per hr - 12 Ton

- Variable Speed Main Drive, Back Drive & Pump

- Bowl Length & Diameter - 80" x 19"

- Back Drive 20hp; Main Drive 125 hp - 4" 20hp Pump

- Power Required 2 - 480v, 100amp, 3w4p

Key Features

-

Full Dewatering and Barite recovery

-

The unit is self-contained other than a generator and is one Non-Permitted Load

Does NOT require a crane or fork lifts to rig up. (can be rigged up in as short as 5hrs)

Rig ups are cut in half from what consumers are used to seeing from other solids control companies. This is due to our patent pending hydraulic lifting system. Also eliminating the need for a crane while rigging up the WER solids control system. -

Light plants will no longer be needed in the backyard

-

Our team is confident that we can lower your solidification usage to almost zero, saving you on materials and disposal tonnage

-

The design of the system and the ease of rig ups/downs, allows for the equipment to stay behind on locations during rig moves and process all dirty water.

-

Due to our efficiency in removing water from the drill cuttings we can re-introduce clean reusable water.

-

WER can minimize and in some cases, eliminate the drill cutting solidification cost.

Flexibility

- The WER solids control system is unique due to the flexibility in operations, more particularly the ability to seamlessly swap from one drilling fluid operation to the next.

- Swapping from the dewatering process to processing of oil based mud is as simple as opening and closing a few valves.

- Eliminating the chance of costly spills do to breaking connections.

- No need to change effluent discharge points.

- The unit is self-contained (other than a generator)

- The design of the system and the ease of rig ups/downs, allows for the equipment to stay behind on locations during rig moves and process all dirty water.

Efficiency

- Rig ups are cut in half.

- No crane needed during rig up.

- Minimize drill cutting solidification cost.